The Single Strategy To Use For Caster Manufacturer

Wiki Article

What Does Caster Manufacturer Do?

Table of ContentsAn Unbiased View of Caster ManufacturerFascination About Caster ManufacturerAn Unbiased View of Caster Manufacturer5 Simple Techniques For Caster ManufacturerCaster Manufacturer Things To Know Before You Buy

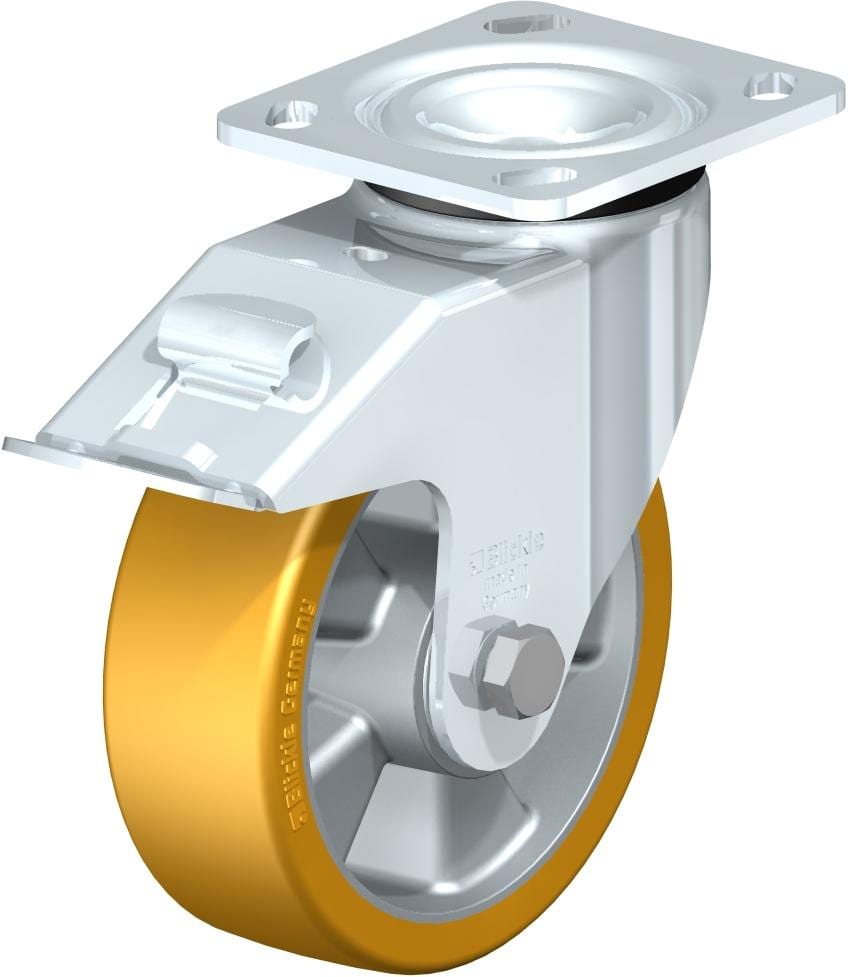

Caster wheels are made use of in purchasing carts, office chairs, clinical beds, and also product handling equipment. Caster wheel variants differ substantially based upon the application demands as well as are widely employed in a vast array of applications. It is a terrific movement enabler, with residential or commercial properties such as stamina, corrosion resistance, water resistance, and weather resistance.

Heavy items need casters with thicker wheels, some bigger objects might require numerous wheels to equally disperse weight. This area will certainly discuss the manufacturing processes entailed in making caster wheels.

Plasma cutting is a sort of thermal cutting that utilizes an ionized gas to reduce the steel. This means that the procedure makes use of warm to melt the steel rather than mechanically reducing it. It's one of one of the most common techniques for reducing thick metal plates, however it's also useful for sheet metal.

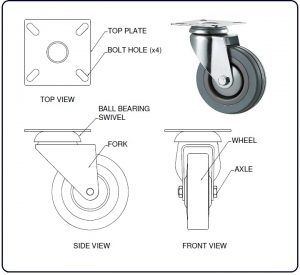

The following component to be reduced is the fork. Forks are the arms that hold each side of the wheel axle. The forks are constructed out of steel coil, a more versatile and thinner kind of steel. The steel coil is rolled out as well as fed into a strike press equipment which damages it with the yoke formed dye.

See This Report about Caster Manufacturer

The press bends the item right into the required form and it additionally makes a round groove around the hole in the middle. The opening is loaded with steel sphere bearings that permit the yoke to rotate.

After captivating the top plate to the yoke, placed a steel seal over the retainer as well as lock it in position with a pneumatic press. The next machining procedure on the production of wheel wheels is the extrusion of the wheel product. To make the wheels, nylon inserts are required. The inserts are put in an injection molding press, which thaw neoprene rubber and infuses it right into the mold and mildew.

The rubber edge takes in shock, lowers sound, as well as protects against damages to the flooring or surface area. For bigger sized wheels, a different molding press is used to suit the called for size. The molding procedure to create the wheel coincides. These bigger molding press equipments typically make one wheel each time.

The steel overviews place the wheel between the yokes and place the steel wheel axle. A bolt head safeguards one end and also a nut is connected to the various other end. Grease is injected to lube the round bearings. The wheel should undergo a collection of quality assurance tests that count the variety of revolutions a caster can hold up against prior to it finally damages.

Some Known Details About Caster Manufacturer

A swivel wheel, on the various other hand, may be a better alternative if useful link there's demand for even more maneuverability. Take into consideration also whether there's requirement for swivel locks, if devices is to be relocated in a straight line - Caster Manufacturer. The capability to relocate something is why wheels are placed on it, but there's also require to know exactly how much liberty there remains in that movement.Numerous applications require a stem mounted caster, although this can restrict the wheel's weight capacity. Sturdy wheels will utilize a plate install to safeguard the caster and spread the tons over a higher installing location. Knowing the installing preference can assist limit the alternatives when picking wheels from a big number.

This inquiry will certainly aid review if there's a requirement for light-duty, medium-duty, or heavy-duty casters based on the total weight that will be put on them. Wheel wheels differ varying with applications that are from clinical, commercial, furniture wheels, and so on.

They are chemical, oil, as well as acid resistant because they are made up of polycarbonate as well as mold-on rubber. While a soft step allows wheels to surrender small debris and is normally quieter than other products, it also makes it much more challenging to roll as well as reduces the caster's total lots capability. Polycarbonate rubber, rubber tread on iron core, and polyurethane tread on plastic core are all common soft walk wheel wheels.

The Basic Principles Of Caster Manufacturer

They are additionally applied in food solution equipment, handling plants, as well as other light to medium lots. Ferrous wheels give the highest possible tons capacity, influence resistance, temperature array, as well as rollability of any caster wheel readily available due to the strong structure it has. Ferrous wheels, as the name implies, are constructed from forged steel or actors iron, making it excellent for harsh like this circumstances such as storage facilities and making factories where floor security is not a top priority.However, strong urethane wheels are one technique to avoid these issues. The worry of walk separation and core deterioration is reduced since the whole wheel is made from shaped urethane without any core. Synthetic wheels with a harder step have a reduced rolling resistance as well as a greater influence toughness and also reliability.

While a lot of artificial wheels are excellent see page for high-impact as well as extreme scenarios, they are louder than softer products and are less forgiving when clashing with debris. Phenolic wheels, which are made of phenolic resin as well as macerated canvas, are a frequent choice for press pull applications. Phenolic wheels are strong and also stand up to oil as well as various other chemicals, making mobility easier.

Gray iron is utilized to make cast iron wheels. Some of the specifications located on this caster wheel include solidity of 90-95A; Brinell 145.

Some Known Questions About Caster Manufacturer.

These wheels have a solidity of 130 150 brinell. Birthing used on these wheels might include: a plain bore, straight roller, and also accuracy tapered roller. Flanged caster wheels can run within a temperature level of 800F given it has proper bearings as well as lubrication. This kind of caster wheel can operate in the list below problems: mild chemicals, oily and greasy areas, as well as steel chips on the surface.

The strong wheels are solid in typical usage, can endure high temperature levels, and also absorb shock and influence without failure. Built steel wheels surpass pliable steel wheels in regards to tons ability, impact strength, and rollability of all caster wheels. Built steel caster wheels can be run on concrete and also smooth steel surface areas.

Bearings that can be made use of consist of plain, tapered, Teflon, and also roller bearings. These caster wheels can run under the same conditions which are light chemicals, oily as well as oily areas, as well as metal chips on the surface. These wheels are made up of a nylon and glass mix as well as are engineered to hold up against severe temperature levels.

Report this wiki page